Sundyne Washdown Systems

All plants have cleaning requirements, and none are more stringent than those faced by plant, maintenance & sanitation managers in the food processing industry. Globally, there are thousands of food & beverage processing facilities that require high pressure wash-down capabilities for cleaning & sanitation, odor control, dust suppression, deboning & scale removal, and for a wide range of processing applications.

Most plants utilize a central, high-pressure cleaning system that allows multiple operators to clean faster, conserve water and use fewer chemicals. For wash-down applications, high pressure is the key to efficiency. The ability to boost pressure on demand enables operators to get the job done with less water, which saves money.

APPLICATIONS

Cleaning and Sanitation

- Belt Cleaning

- Equipment Washdown

- Surface Cleaning

- Central Cleaning Systems

- Tank Cleaning

- Barrel Cleaning

Processing

- Fish Scale Removal

- Crab Cleaning

- Poultry Deboning

- Livestock Processing

- Hatchery

High Pressure Mist

- Greenhouse Misting

- Odor Control

- Dust Suppression

- Livestock and Poultry Cooling

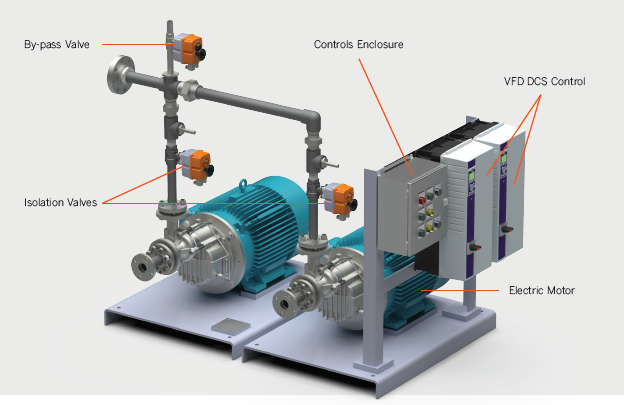

Fully Integrated, Pre-Engineered Turn-Key System – SundWASH Prime™ can be configured to any process requirement and fully field adjustable. The integrated Variable Frequency Drive adapts to changing operation requirements. The control logic optimizes single or multi-pump cascade operation and can alternate usage across installed pumps. The system can communicate with the plant DCS for back-office control via Ethernet protocols.

Constant, Pulsation Free Pressure on Demand – There is no waiting for pressure to build up, and there are no drops in pressure with increased flow requirement. SundWASH Prime’s Integrated Variable Frequency Drive adapts to changing operational requirements and can support multiple operation modes.

Energy Savings – An intelligent minimum flow by-pass opens only when required. The system goes in stand-by or sleep mode when not in use. The Sunflo pump is close coupled to a NEMA premium efficiency motor.

Field Serviceable – Sunflo pumps, which are the heart of the SundWASH Prime systems, feature easy-to remove cartridge assemblies that can be repaired in place, by one person, with one wrench, in less than an hour.